A Stainless Steel Steam Coil for FBD (Fluidized Bed Dryer) is an essential component used in the pharmaceutical, food processing, and chemical industries. FBDs are widely used for drying powders, granules, or other solid materials by suspending them in an upward airflow, ensuring efficient drying. The steam coil plays a pivotal role in providing the necessary heat for the drying process by efficiently heating the air within the system.

Stainless Steel Steam Coil for FBD is a critical component for ensuring efficient and effective drying in various industries. By providing optimal heat transfer, enhancing system durability, and maintaining hygienic standards, these coils play an essential role in achieving the desired product quality and minimizing operational disruptions. Their corrosion resistance, thermal conductivity, and ease of maintenance make them a reliable choice for many industries requiring fluidized bed drying systems.

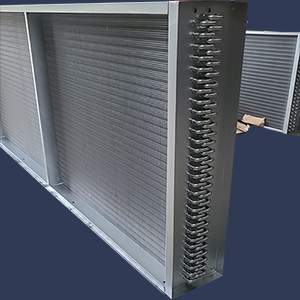

The Stainless Steel Steam Coil is designed to transfer heat from steam to the fluidized air within the FBD. The steam coil operates by circulating steam through a series of stainless steel tubes. The heat energy from the steam is transferred to the surrounding air, which in turn is used to dry the material. This process ensures uniform temperature control and prevents overheating, which can damage the material being dried.

Stainless steel is the material of choice for manufacturing steam coils due to its numerous advantages. It is highly resistant to corrosion, especially when exposed to moisture and steam over time. Stainless steel also provides excellent thermal conductivity, ensuring efficient heat transfer. Additionally, it can withstand high temperatures, making it suitable for industrial applications such as FBD systems, where precise temperature control is required for optimal drying performance.

The steam coil is constructed using high-quality stainless steel, often in the form of seamless or welded tubing. These coils are designed with varying diameters and lengths to meet the specific requirements of the FBD system. The coils are strategically placed within the system to maximize heat transfer efficiency. In many FBD systems, the steam coils are installed inside or around the drying chamber to ensure that the hot air is evenly distributed, further enhancing the drying process.